PAPER&PULP

Large amounts of energy, in the formof heat and electricity,are required forall the processes involved in pulp andpaper manufacturing.Reducing the overall consumption of energy is therefore a prime focus,leading to careful of heat recovery solutions.

We enable you to recover maximum heat energy from most process fluids-fibrous or not – with low installation,operating and maintenance costs.

The closer the temperature approach between two fluids in a plate heat exchanger,The closer the temperature approach between two fluids in a plate heat exchanger,We can enable you to achieve as close a temperature method as possible.

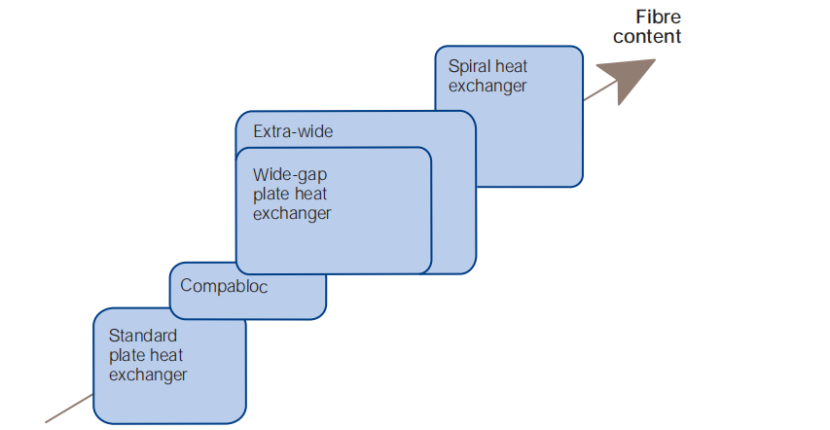

Dealing with fibrous fluids

Operators of pulp and paper mills often have to deal with the fact that one or both process fluids contain fibres and solid matter.

You benefit from a full range of heat exchangers fully capable of handling fibrous fluids while still providing high thermal efficiency and thus maximum heat recovery. Full access on both sides also ensures easy cleaning, should this prove necessary.

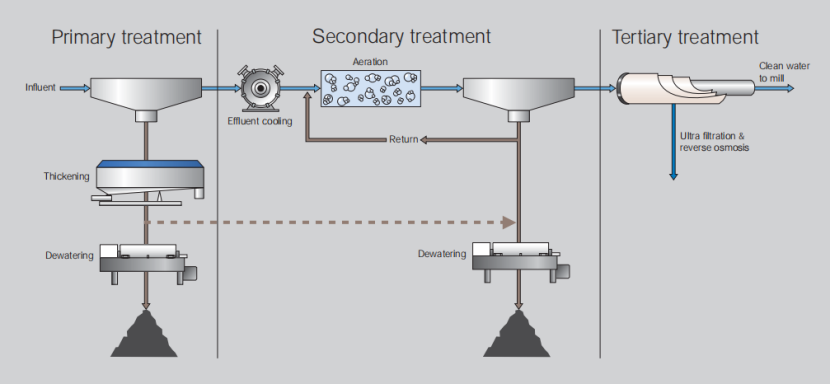

Reduced wastewater treatment costs

The production of pulp and paper demands water in large quantities for virtually all the processes involved. Even with some recycling, pulp processing and paper making still require large quantities of fresh water.We can help you minimize water usage and optimize your economy waste water treatment.

● lower operating costs due to reduced polymer consumption, no filter aids and fully automated operation

● reduced installation costs due to compact size

● minimum disposal costs and maximum water recovery due to higher cake dryness and clearer effluent In addition to enabling you to treat and Maximum recovery of waste water efficiency, also provides Equipment that can be reduced Your plant's water usage.

To be a front runner in your part of the pulp and paper industry, you need strong support from your service provider. Not just to solve problems as they arise, but also to help you optimize the performance of your particular industrial processes.