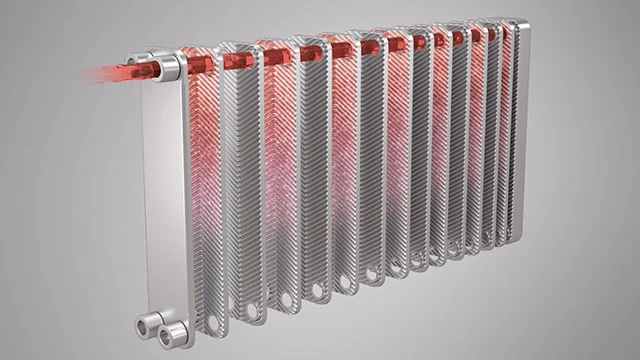

Fusion welded plate heat exchanger:

Fusion welded plate heat exchangers technology creates highly efficient, compact heat exchangers made entirely of stainless steel. Virtually maintenance free and capable of handling extremely high pressures and temperatures, they are an ideal heat transfer solution for challenging applications. These include duties with high cleanliness demands, with aggressive media such as ammonia, or where copper or nickel pose contamination risks.

When nickel and copper just won’t do

In applications with high hygiene demands, all equipment must conform to the strictest standards. For drinking water applications in particular, where protecting consumer health is a top concern, preventing the possibility of nickel and copper contamination has become a critical issue. As a result, more and more OEMs are seeking heat exchanger solutions for clean water chiller and tap water heating systems that do not use these metals.

Built in 100% stainless steel, Fusion welded plate heat exchangers are an optimal choice when nickel and copper just won’t do. In addition to providing peace of mind when it comes to hygiene, they also offer much higher efficiency than traditional copper and nickel-free solutions used for these duties.

Brand:

Acme has been engaged in the research and development, testing, production, manufacturing and sales of heat exchanger equipment as a professional manufacturer, with a plant area of 10000 square meters. At present, it has a professional production line of complete machines, plates and rubber strips, hundreds of sets of plate molds of various models of heat exchangers and thousands of sets of rubber pad molds of world-class brands. It can not only meet the different use requirements of various complete machine users, but also provide the majority of plate heat exchanger users with various plates, rubber pads and maintenance services from foreign manufacturers.